SAFETY & LEGAL STUDIES

Truck Safety

EFSS Fall Protection Engineering for Truck/Trailers

For Trucking Fall Protection needs including Concept,

Products and Engineering Contact Ellis Fall Safety Solutions

302-571-8470 to discuss your applications.

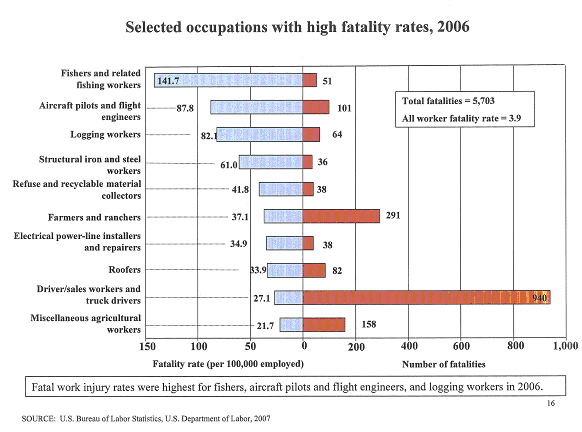

Truck/Trailer Driver Fatalities on the Rise – U.S. Government Statistics

Articles:

“Tarping Flatbed Trailers” By J. Nigel Ellis

Professional Safety Magazine May 2008 “Truck Falls” By Robert McClay

Professional Safety Magazine May 2008 “The Lowdown on Safe Tarp Handling “ By Pete Van Dyne, Ted Christiansen

Occupational Health & Safety June 2006

Presentations:

“Fall Protection on Stationary Trucks”, By J. Nigel Ellis ISFP Symposium June 2008

| Driver’s Role | Shipper’s Location | ||

| A Driver’s own Access to Flatbed, Or Shipper/Receiver provides (eg. Anderson Ladder or equivalent) | Walk Trailer Deck | COB | COB |

| B Walking Deck/Climbing Load fall protection options: | |||

| 1. Side Kit | Walk deck only | COB *** | COB *** |

| 2. Push up platform | Access to Walk deck only | 3 | X |

| 3. Guardrail on Trailer edges/rub rail | Walk deck only | 3 | 5 |

| 4. Adapted Forklift Tarping | Stay on ground | 3 | 5 |

| 5. Net System | Walk deck only | 3 | X+ |

| 6. Powered tarping system | Stay on ground | 3 | 5 |

| 7. Crane Spreader Bar | Stay on ground | 3 | 5 |

| 8. Soft Sides | Climb to tie-down load | COB ++ | COB++ |

| 9. Rolling (Sliding) Tarp | Stay on ground | COB | COB |

| 10 Overhead HLL (T’s, L’s) * | Climb Load | 3 | 5 |

| 11. Shipper’s forklift operator | Driver benefits if tarp lifted on top of load | 5 | 5 |

| 12. Loosen tarp straps and pull tarp off | Stay on ground | 5 | 3** |

| C Miscellaneous Fall Protection applications: | |||

| 1. Tank Truck top Fall Protection | Climb ladder to bleed tank | COB | COB |

| 2. Tank Car drop down rails | Climb atop tank car | 3 | 3 +++ |

| 3. Hopper Car transfer | Attach to overhead Lifeline | 3 | 3 |

| 4. Roll-up stairs for tank car | Climbing portable stairs | 3 | 3 |

| 5. Dump Truck Automatic Tarp | Stay on ground | COB | COB |

| 6. Transport Trailer edge clean up (sketch) | Climb into if necessary | 3 | 5 |

| 7. Flatbed Loading concrete slab | (no Fall Protection shown Unhook Load) | 5 | 5 |

| D Future Concepts: | |||

| On-board Lifeline System (Double SRL) | Climb Load | COB | COB |

| E Driver’s own hard hat: | |||

| (Type II Head Protection for 11ft max. fall elevation) | Walk Deck / Climb Load | 3 | 3 |

| COB = Carry On Board fall protection by truck line or independent operator driver usable at shipper’s and receiver’s locations. 3 = Shipper’s choice of fall protection at their facility, some receiver’s have fall protection 5 = Receivers typically have no fall protection but can consider investing in Fall Protection system of their choice for predictable incoming shipments, except for construction sites * Engineered Horizontal Lifeline System (HLL) posts are L or T- shaped for single or two bays + Unless truck mounted then COB ++ Tie Down of tall load is still a fall hazard that requires a rolling bar and SRL or equivalent +++ Most rail yards have overhead fall protection for employee tank car unloading º Desired Throughput rate determines number of systems or bays required ** Pull tarp off Load is Key technique to avoid fall exposure. If tarp sticks, receiver’s fork lift cage access can help *** Side kit have edge fall hazard, need B2 or B3 | |||

EFSS capabilities in the Transportation Industry include:

- Discussion of needs at Shipping and/or Receiving docks

- Fall System alternatives

- Design engineering drawings of structure for tarping buildings and /or platform and horizontal lifelines

- Construction oversight

- Meeting IBC ( Int’l Building Code) and ANSI Z359-2007 Fall Protection Code requirements

- Prototype systems (D)